News

Menu:

H-Ray S&T Commits to Delivering Solutions for Clean Energy Applications

- Page Views:249

- Publication Date:2025-04-25

The global energy landscape is undergoing profound transformation, with strong momentum toward green, low-carbon, and zero-carbon transition—presenting both challenges and opportunities. Leveraging its abundant natural resources, Hainan Province is accelerating the development of a world-class free trade port with Chinese characteristics, driving the construction of Clean Energy Island 2.0 to support the region's green and low-carbon development.

The Comprehensive Energy Systems Committee of the Chinese Renewable Energy Society is dedicated to building a renewable energy-dominated new power system to facilitate the green energy transition. Against this backdrop, the Committee, in collaboration with the Hainan Renewable Energy Association, will host this conference in Haikou from April 25–27, focusing on the theme: "Clean Energy Island 2.0: Green and Low-Carbon Development for Hainan."

The event will explore pathways to establish a renewable energy-based new power system, supporting Hainan’s transition toward a low-carbon, green future.

Professor Yang Hui, Chairman of Shanghai H-Ray and Vice Director of the Hydrogen Energy Committee of the Chinese Renewable Energy Society, delivered a keynote report titled "PEM Water Electrolysis Hydrogen Production and Application Exploration" and participated in the high-level panel discussion on "Integrated Power-Hydrogen Development and Multi-Energy Complementary Ecosystem Construction".

In his presentation, Professor Yang showcased H-Ray's latest R&D achievements and practical applications in proton exchange membrane (PEM) water electrolysis technology. He emphasized that PEM electrolysis, with its outstanding advantages such as wide power fluctuation tolerance and high dynamic response capability, is poised to become the preferred technology for off-grid hydrogen production from renewable energy sources. These innovations are designed to provide cutting-edge solutions for the development of Hainan's Clean Energy Island 2.0 initiative.

Background and Challenges: National Hydrogen Strategy and Market Demand

As a critical component of China's national energy strategy, hydrogen demand is projected to grow tenfold by 2050, with an estimated $2.5 trillion industry value. China aims to increase hydrogen's share to 5.5% of end-use energy by 2030, targeting 100GW of electrolyzer capacity – including 20% PEM electrolysis (proton exchange membrane), representing a hundred-billion-yuan market.PEM water electrolysis, with its clean operation, high efficiency, and rapid dynamic response, has emerged as the key pathway for renewable energy integration.

H-Ray's Breakthroughs in PEM Hydrogen Production

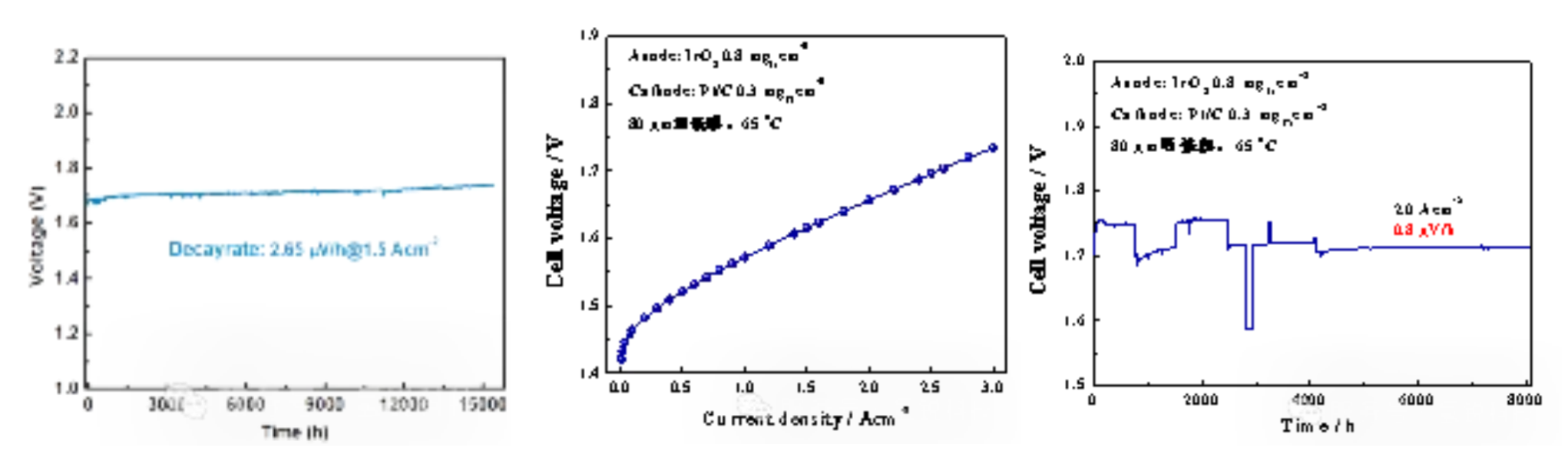

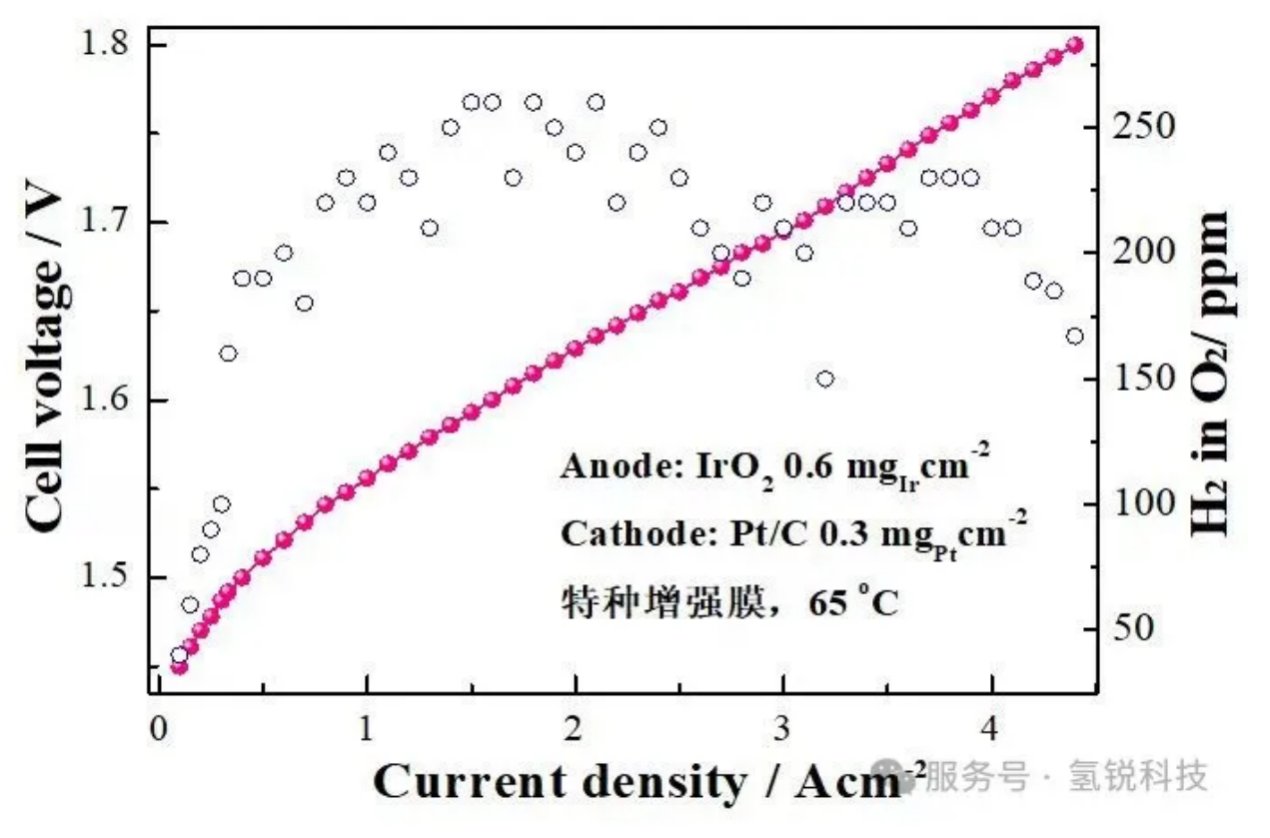

H-Ray has achieved significant breakthroughs in PEM electrolyzer manufacturing through roll-to-roll mass production, delivering membrane electrodes with a 4000 cm² active area while maintaining ultra-low precious metal loading of just 1.1 mg/cm². The company's precision manufacturing processes ensure exceptional coating thickness control (≤±2%) and minimal catalyst loading deviation (≤2.4%), resulting in outstanding electrochemical performance of 1.71V at 2.0A/cm² with remarkable batch-to-batch consistency (≤10mV variation). These technical advancements enable industry-leading durability, with a design lifespan exceeding 100,000 hours and verified degradation rates of ≤1μV/h over 8000 hours of operation, demonstrating H-Ray's capability to produce high-performance, cost-efficient PEM electrolyzers for commercial-scale renewable hydrogen production.

The next-gen product from H-Ray will deliver breakthrough performance with cell voltage ≤1.67V at 3.0A/cm² and rated energy consumption ≤4.0kWh/Nm³ H₂ at 3.0A/cm², representing a significant advancement in PEM electrolysis efficiency that pushes the boundaries of current industry standards while maintaining the company's hallmark reliability and cost-effectiveness for large-scale green hydrogen production.

·Hyzer series electrolyzer stacks: Developed from single stack to MW-scale electrolyzer stacks, featuring high current density (≥2.0 A/cm²), low energy consumption (≤4.07 kWh/Nm³), wide power fluctuation range (10%-110%), and second-level dynamic response capability.

·Ryzer-Cab cabinet-type PEM water electrolysis hydrogen production system: Incorporates compact, skid-mounted, redundant and explosion-proof design with automatic safety interlock control to enhance safety rating, featuring intelligent control for one-button start/stop operation. The system demonstrates low energy consumption, wide power fluctuation tolerance and fast response characteristics.

·Ryzer-Con skid-mounted integrated hydrogen production equipment: Achieves energy consumption as low as 4.5kWh/Nm³ H₂, adapts to power fluctuation range of 10% to 120%, achieves hot start time as fast as 5 seconds, hydrogen purity ≥99.999%, design lifespan ≥80,000 hours, with safety system adopting "prevention-protection-suppression

·-venting" quad-protection design to achieve ultra-low hydrogen-in-oxygen concentration, meeting stringent industrial safety standards.